PRODUCT

1 Carved from pure ingots

Just 0.6 mm thick

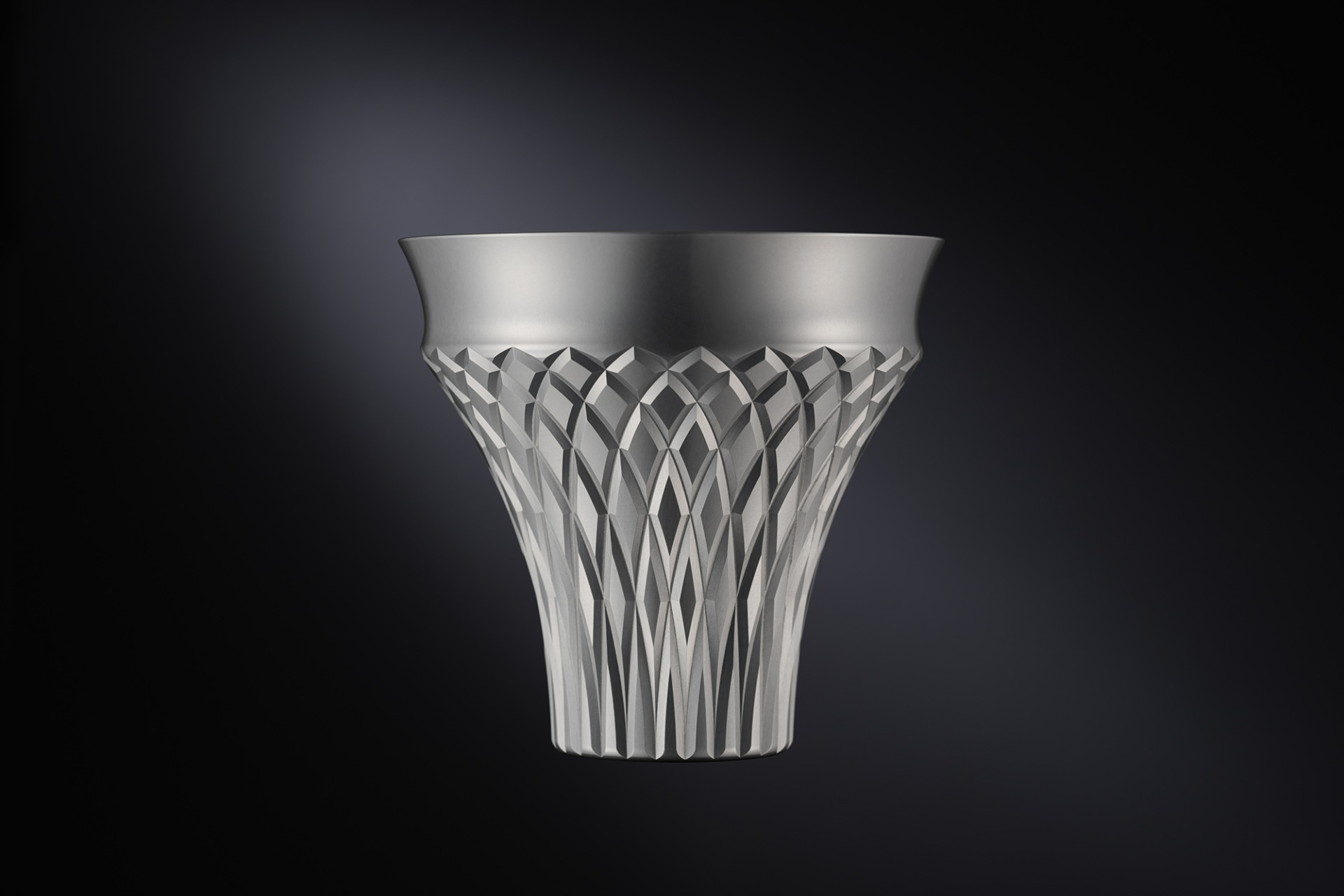

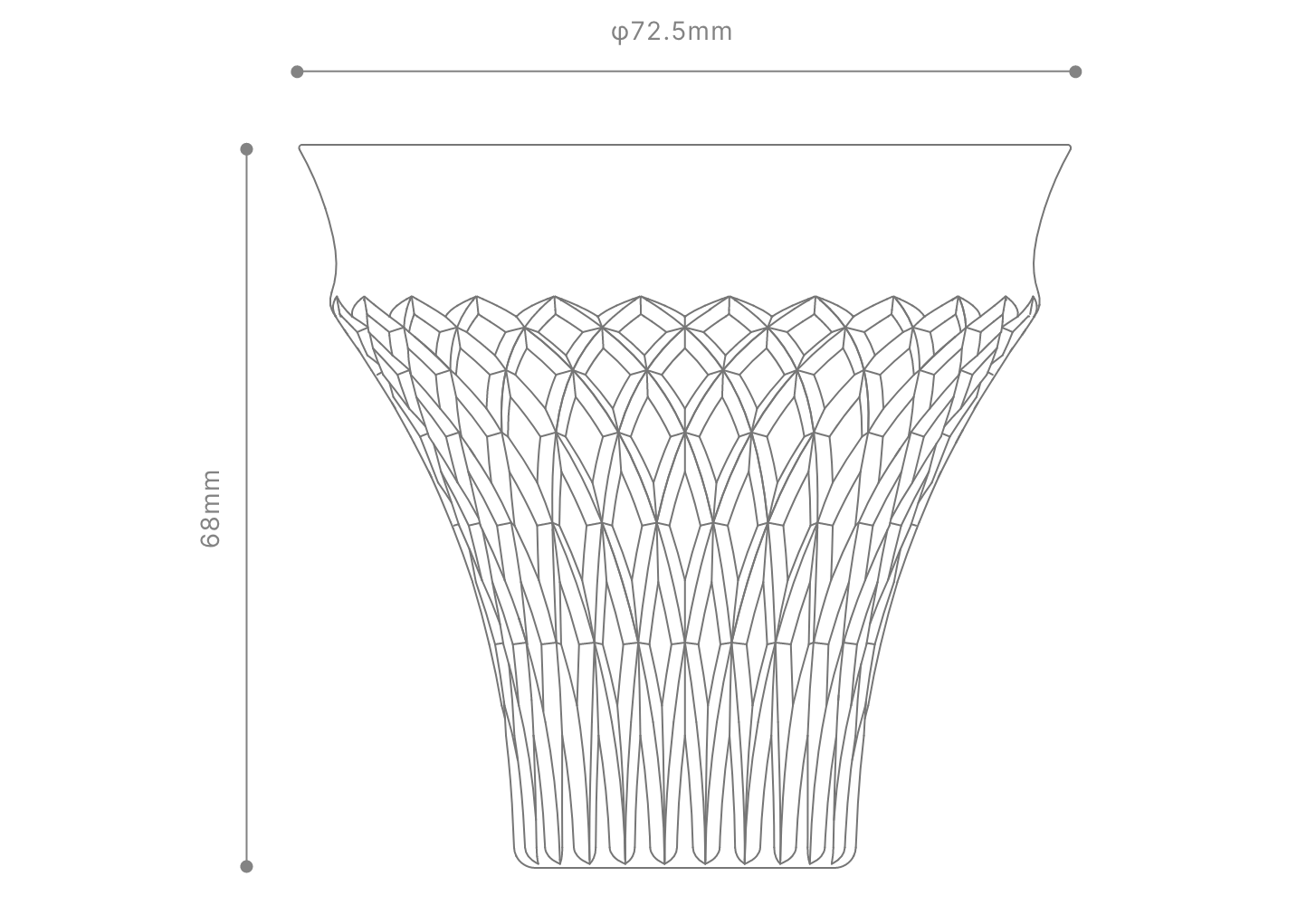

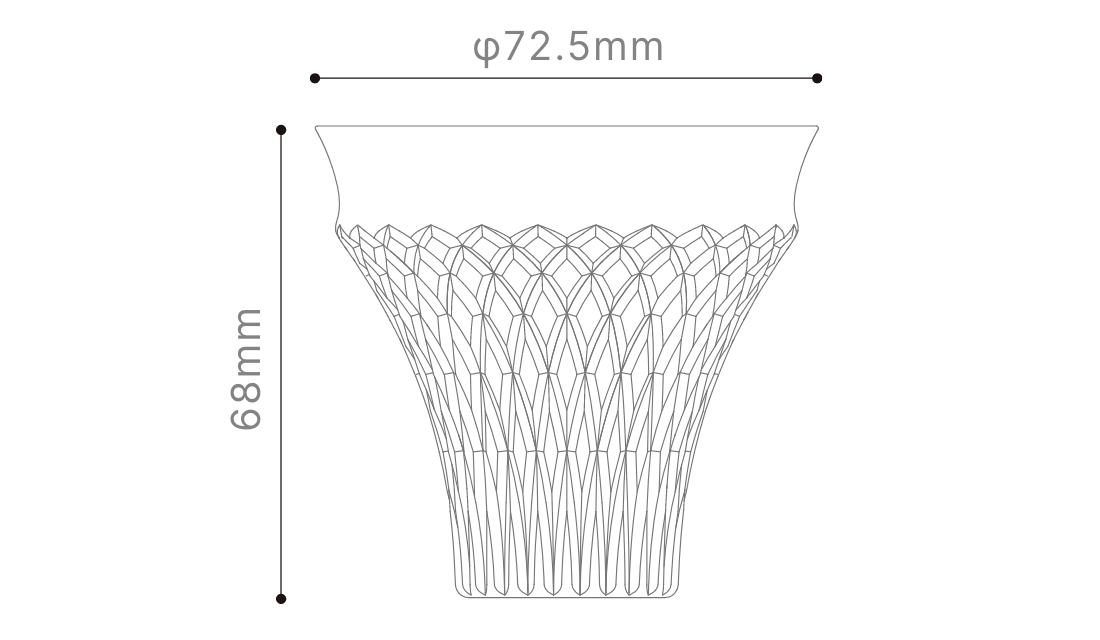

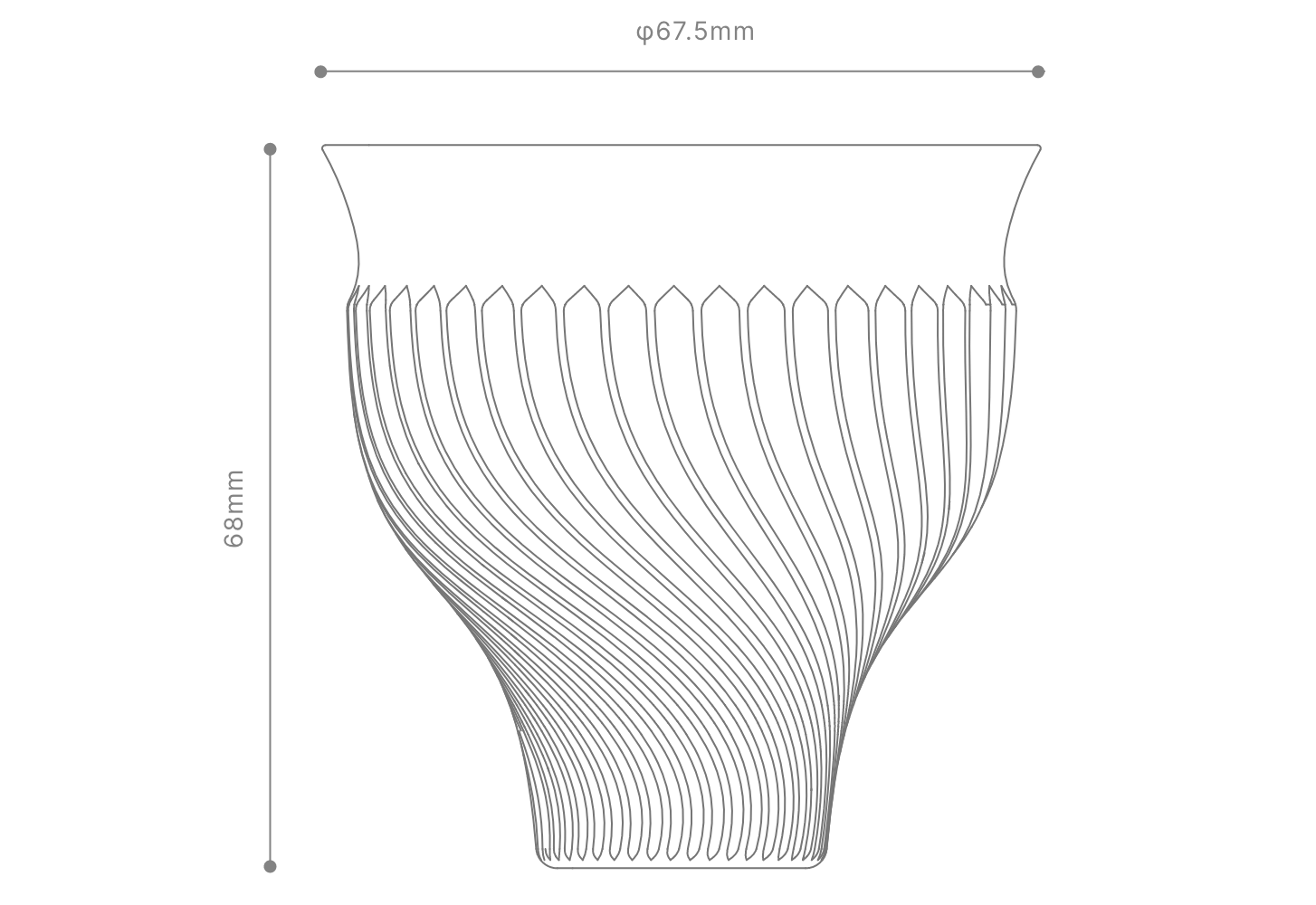

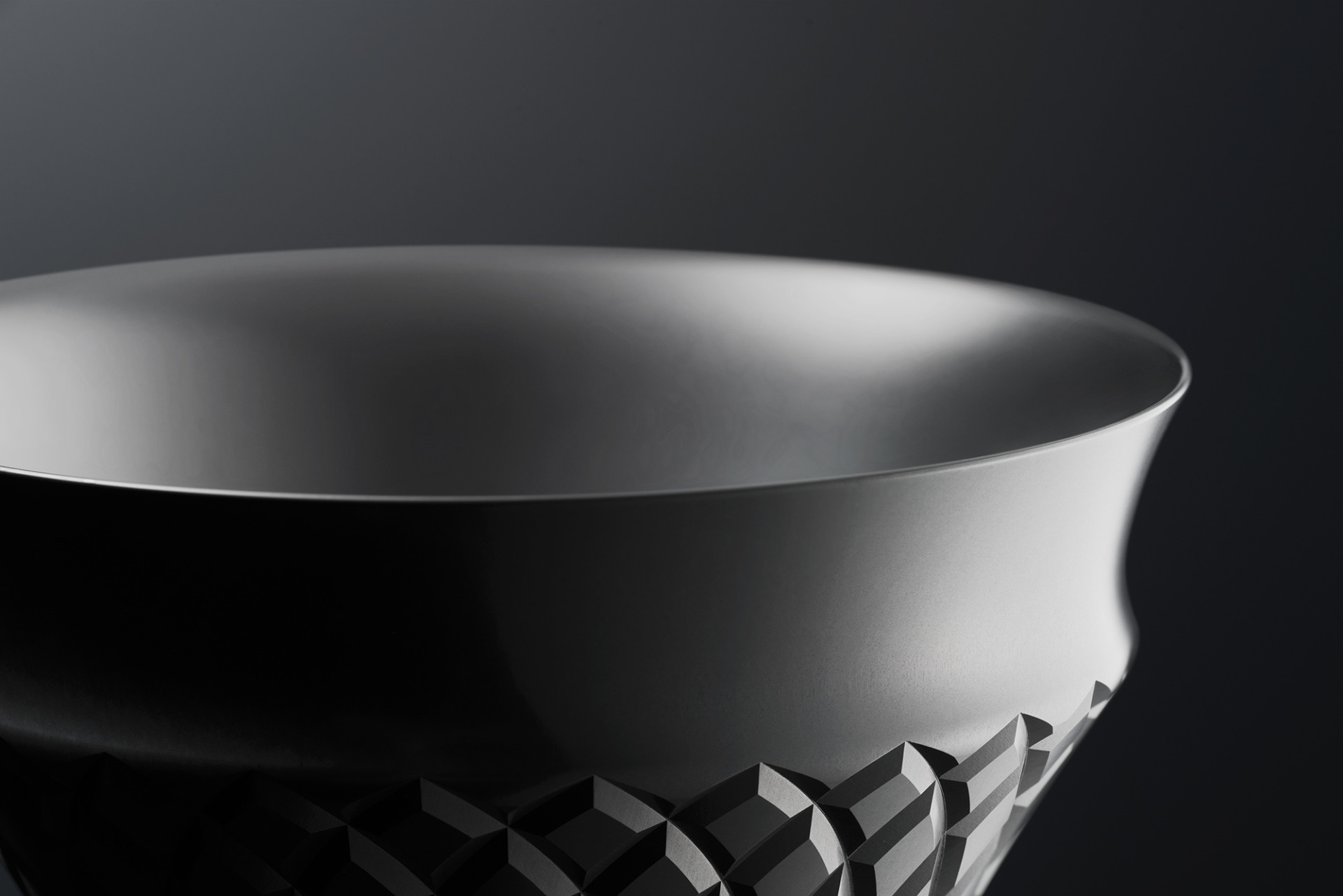

We say “thin,” but thinness has its limits. An excessively thin lip can be disquieting and, in turn, spoil the drinking experience. As part of our development process, we created a series of prototype vessels with lip thicknesses at intervals of 0.1 mm. After various taste tests, we came to the conclusion that 0.6 mm was optimal. We made the surface profile of the lip as round as possible; by ensuring a smooth curve where the cup meets flesh, we have achieved a mouthfeel that is at once gentle and incisive. With its bell-like shape, the cup is also ideal for enjoying the aromas of the sake it contains.

2 Combining the high thermal conductivity

of super duralumin with the highest levels

of strength and hardness Combining the high thermal

conductivity of super duralumin

with the highest levels

of strength and hardness

Savor the coolness of sake

“Hanabie” refers to sake that has been cooled to around 10˚C. Super duralumin is a metal with high thermal conductivity; it allows the chill of hanabie to be transmitted more fully to the lip of the cup, providing clarity to its flavors. Drink chilled sake from these cups for an unsurpassed drinking experience.

An almost-unbreakable material

Super duralumin is among the hardest and strongest of all aluminum alloys. It is used to make airplane parts, which are required to be both lightweight and durable. Our sake cups are therefore exceptionally tough, and promise to remain intact for many years.

3 Cut with precision and beauty

Cut with precision and beauty

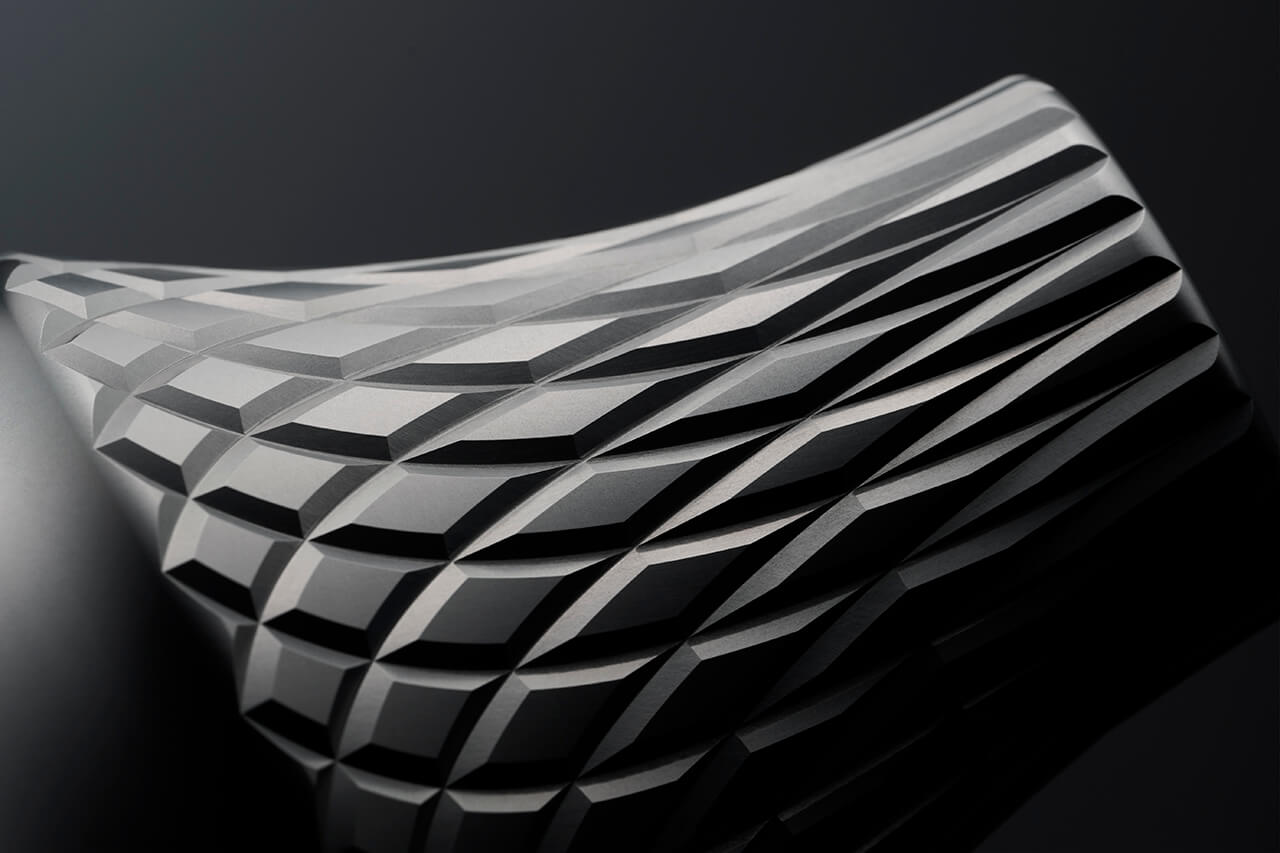

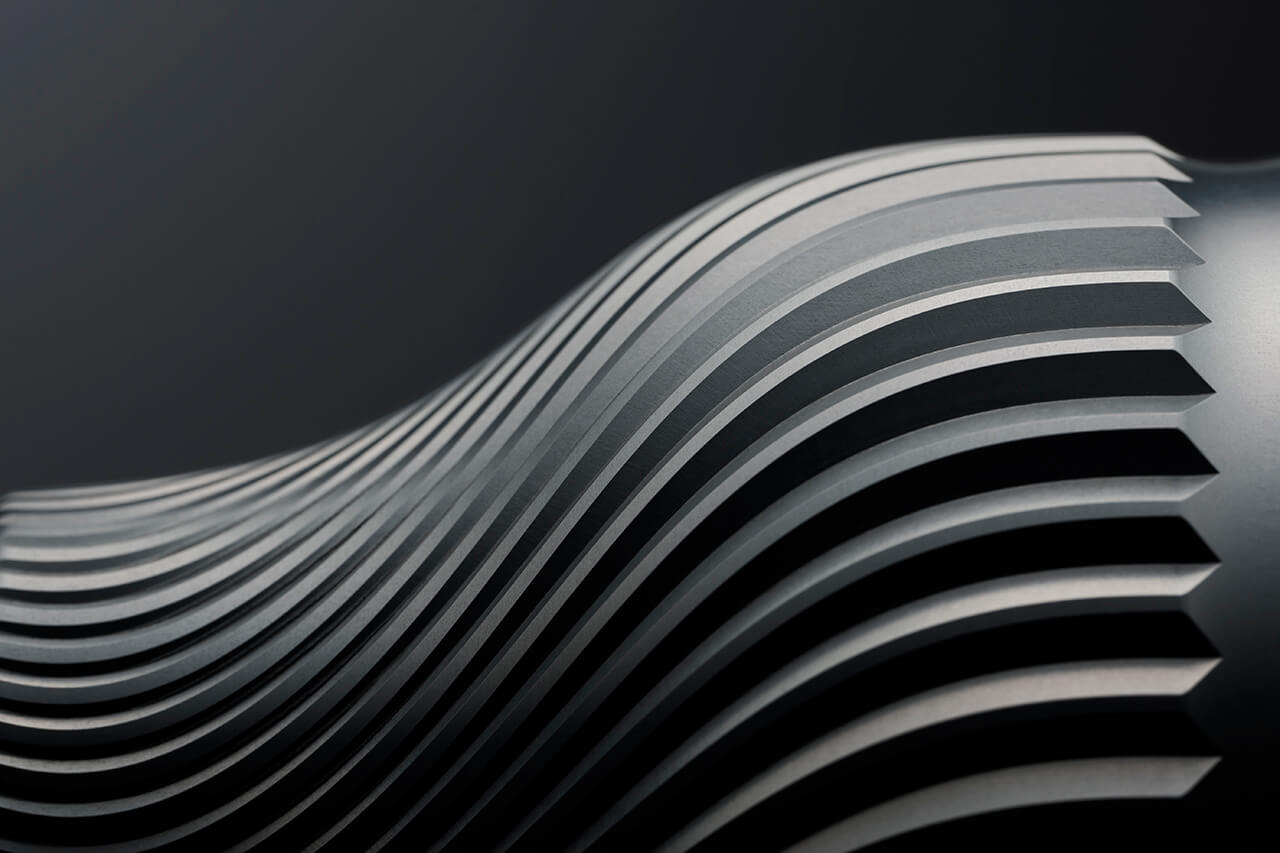

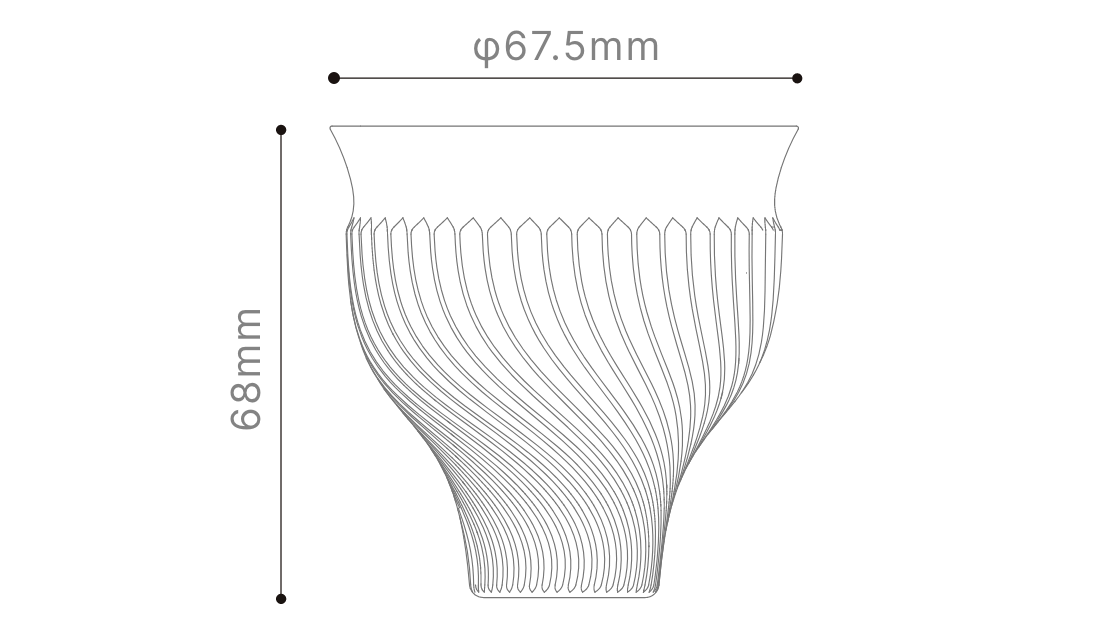

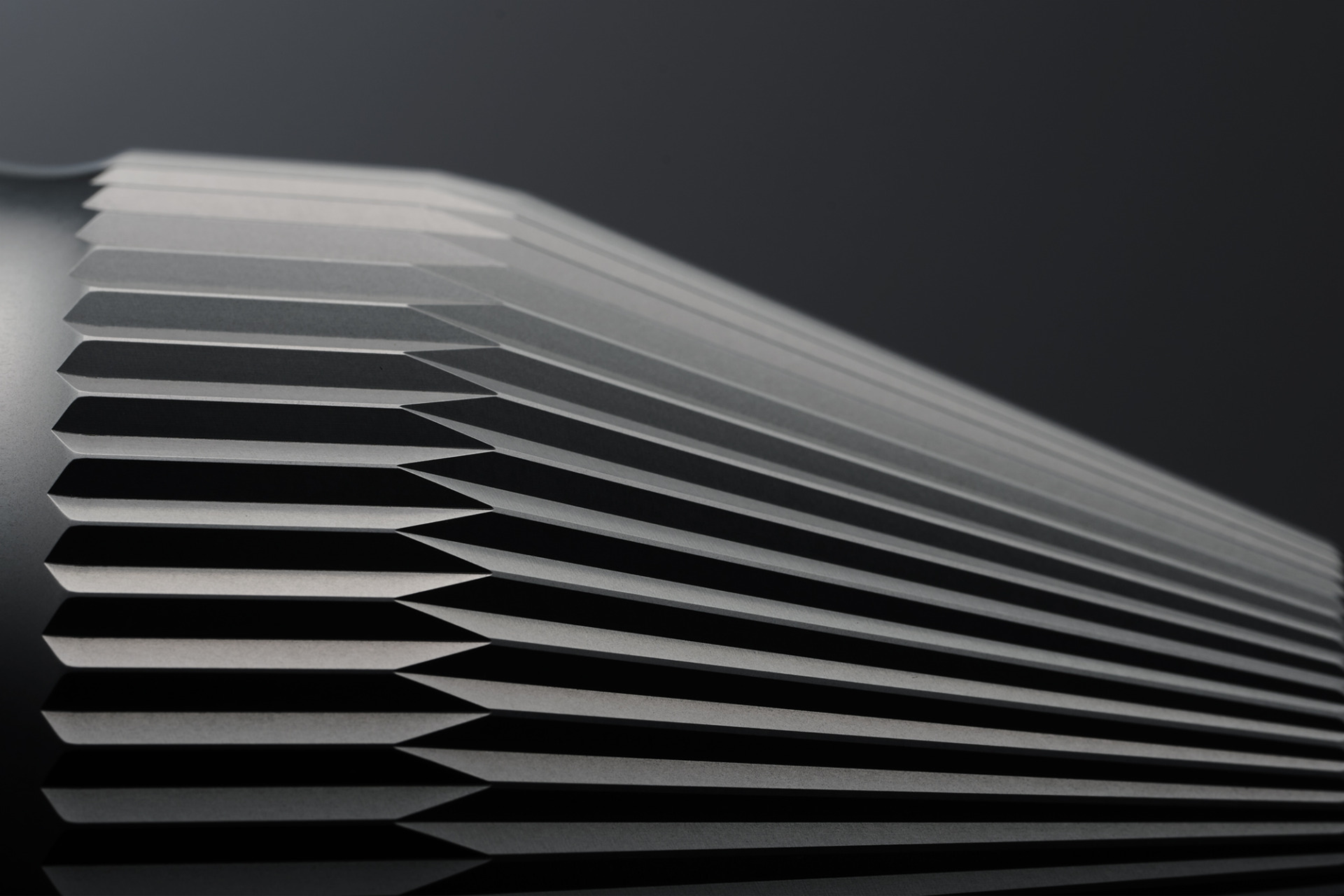

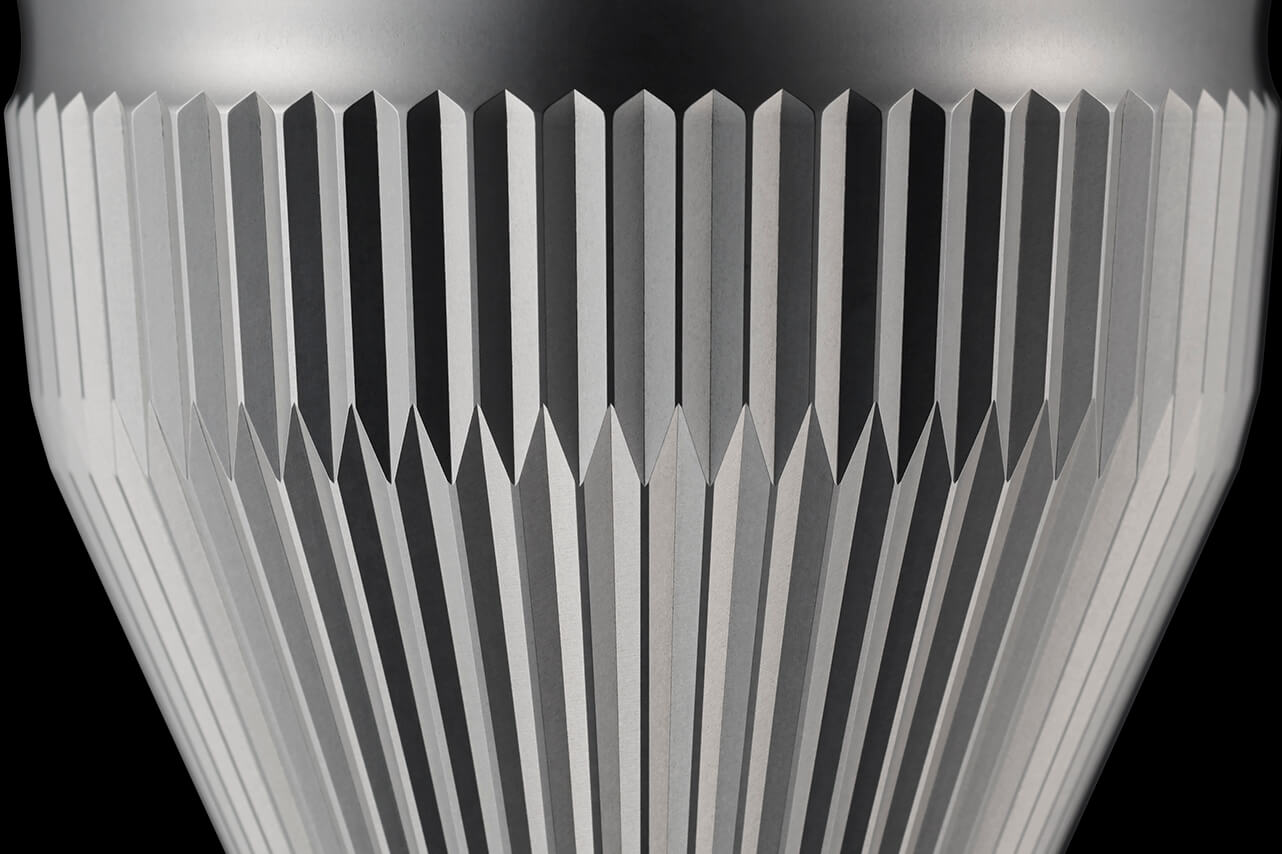

Inspired by the kiriko style of traditional Japanese cut glass, we created these facets through intricate patterns of straight and curved lines; the result is a style that might accurately be called “metal kiriko.” Our processing technologies enable us to make products that clear the stringent safety standards of the aircraft and aerospace industries—and our sake cups are fashioned using these same technologies. The Japanese cut glass that inspired the patterning on our cups is known as “kiriko,” and the metal dust that results from metal cutting is also known as “kiriko.” An unexpected serendipity.

Minimize changes in temperature

with kiriko facets

The distinctive patterning on our cups is more than just decorative. The surface ridges reduce the contact area with your fingers, and prevent the sake from being warmed by your hand. Far from merely ornamental, these facets combine exquisite form with proven function.