PROCESS

1Carved from pure ingots

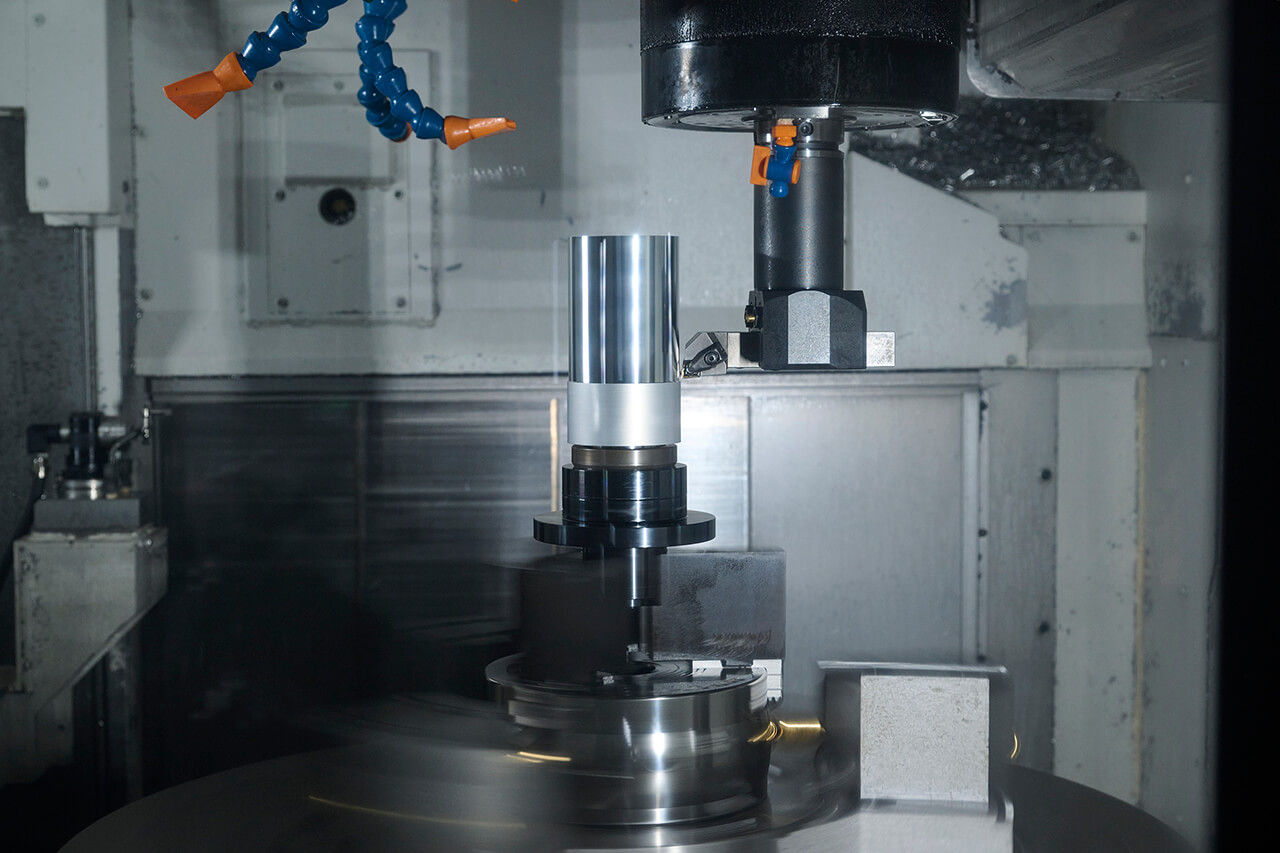

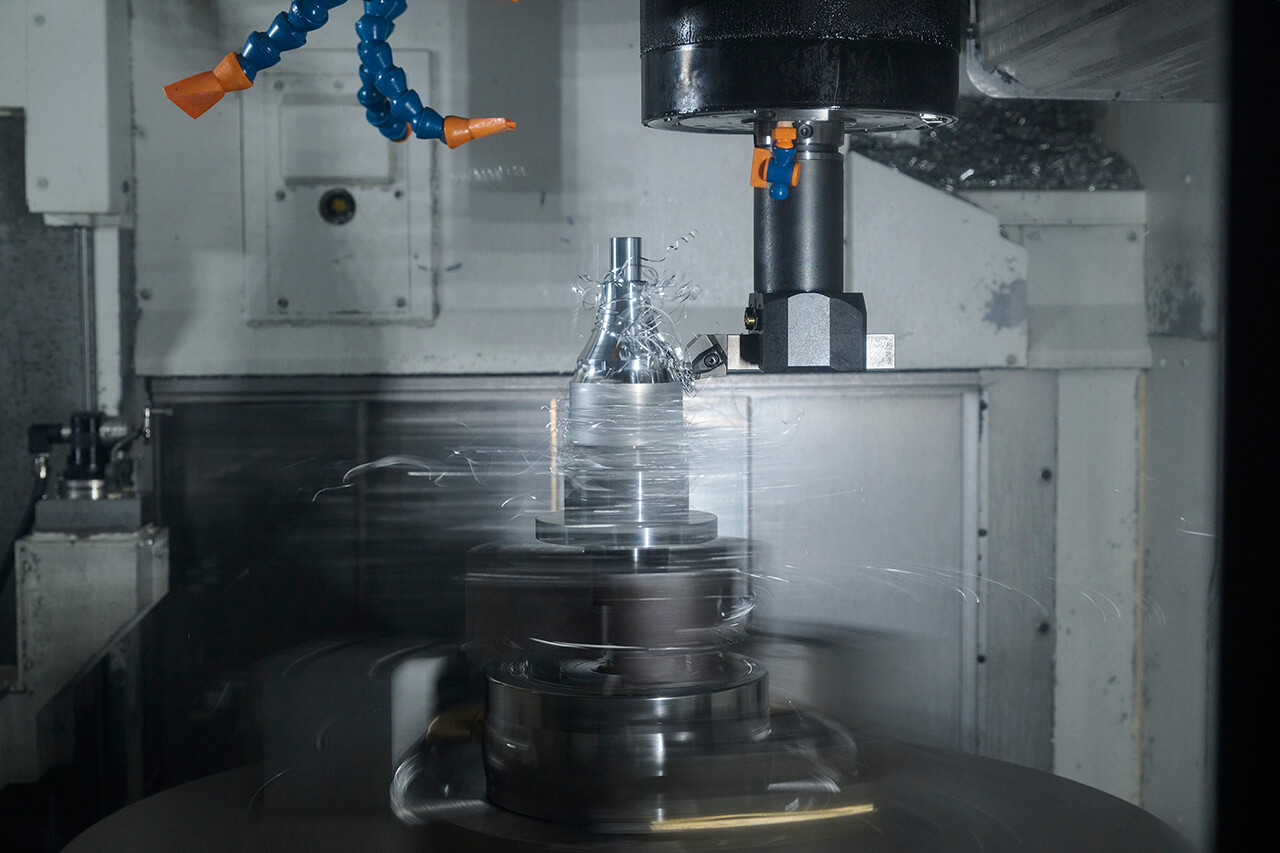

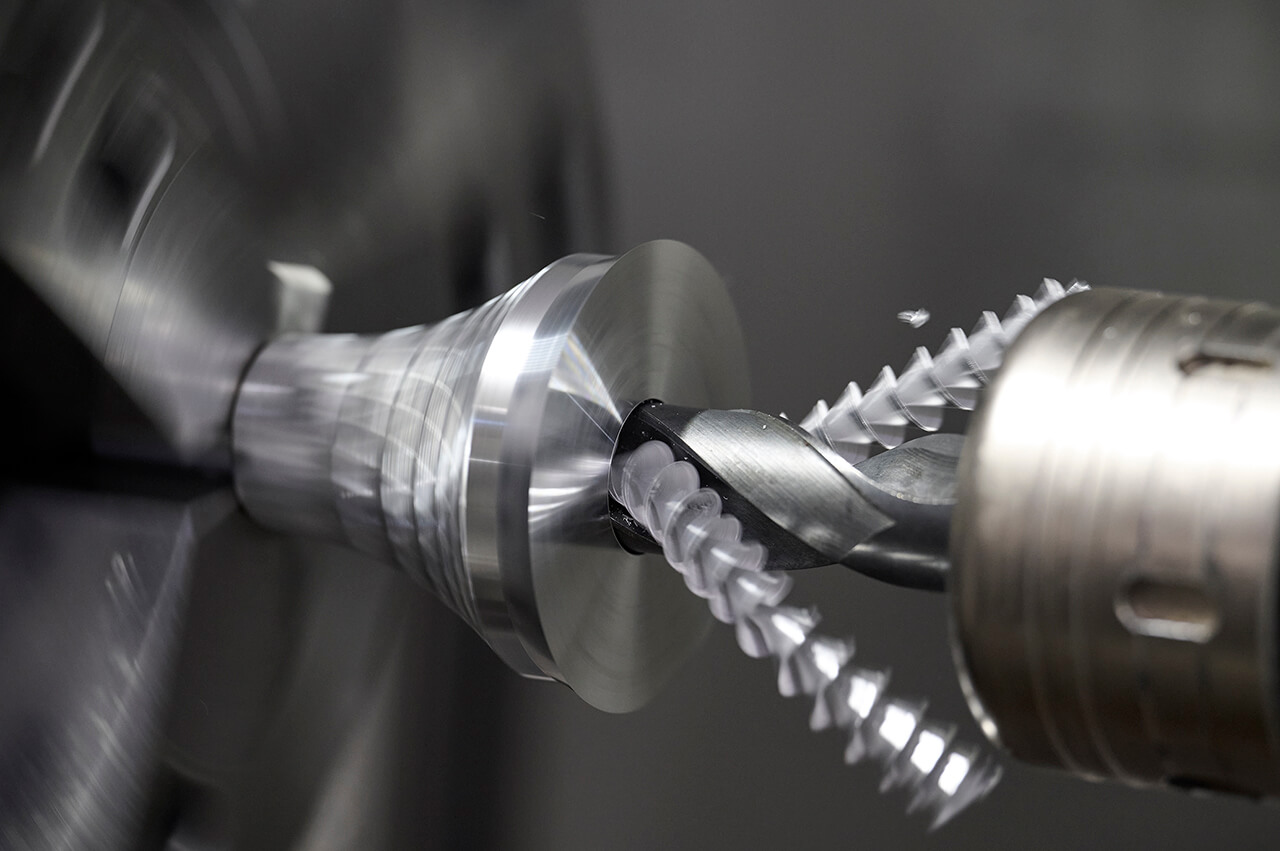

Five-axis and multitasking machining tools

Our cups are extravagantly carved from pure ingots of super duralumin. We use multiple machines—including a five-axis machining tool, and a multitasking machining tool—to cut shapes with high degrees of complexity. We take our time to guarantee superb levels of precision. The skill of our technicians is evident at each stage of the production process—indeed, they are indispensable to the enviable quality of our sake cups.

2The optimum thinness

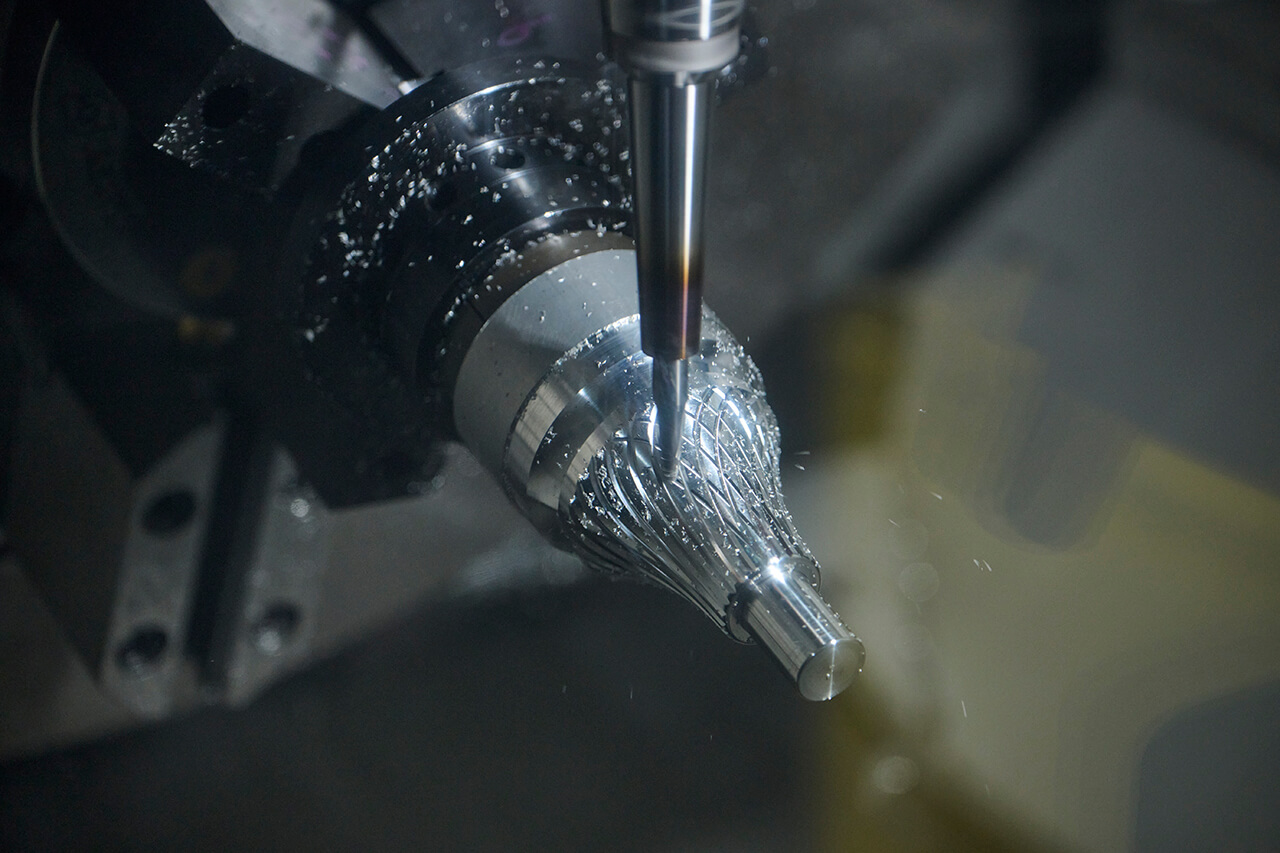

3Precise to 0.0001 mm

Cut with precision and beauty

Measuring to a precision of one-ten-thousandth of a millimeter, and utilizing inspection techniques forged in an industry that permits no inaccuracies, we have created a lip with a thickness of precisely 0.6 mm.

4Recycling super duralumin shavings

Carving sake cups from ingots of metal is a process that generates large amounts of metal shavings. These shavings are extremely pure, and so we collect and melt them down for reuse.